- >CALL ☎

- >TEXT 💬

Crawlspace Spray Foam Insulation

Advanced Insulation Science that outperforms all other types of insulation

Our expert technicians use industry-leading materials to deliver a seamless, air-tight seal in your crawlspace, maximizing energy efficiency and creating a safer and more comfortable living environment for you and your family. Schedule your free estimate today and start experiencing the benefits of exceptional insulation!

Crawlspaces & Basement Insulation and Remediation

There may not be an area of the home that creates a bigger hazard to the occupants' health than that of a typical crawlspace.

Most homes with crawlspaces are not properly insulated for moisture control and this can pose health concerns for the occupants, especially children.

Lack of properly sealed and insulated crawlspace can allow deadly and odorless gases to affect occupants. It can also become a breeding ground for insects, rodents and mold. In addition, it could cause damage to the foundation and the floor system.

The Stack Effect

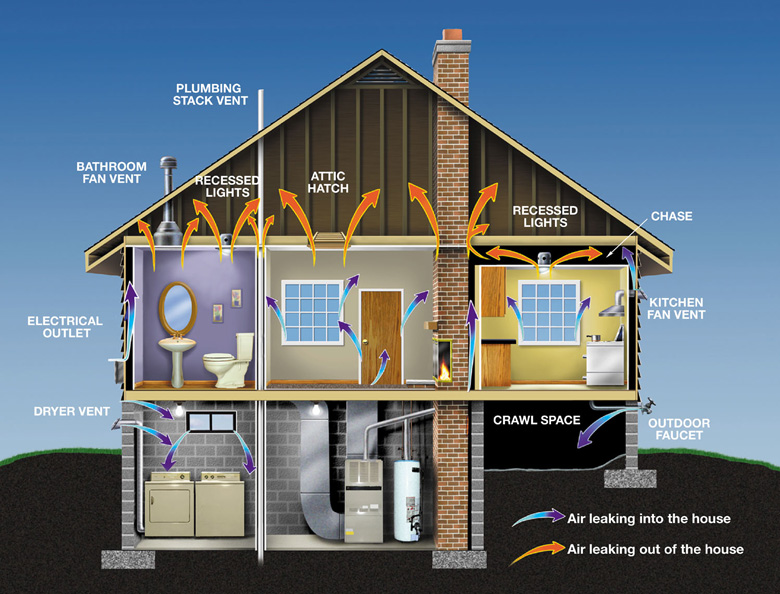

The Stack Effect Graphic shows where air will infiltrate a home even if you have proper window and door sealing.

Crawlspaces are often damp, humid spaces due to water runoff from rain, irrigation systems or an elevated water table. While the building code requires crawlspace ventilation, this ventilation does virtually nothing to mitigate moisture problems and can actually make moisture problems worse.

Houses operate like chimneys.

If you introduce a hole at the bottom of a chimney, a natural draft ensues as air exits the top of the chimney.

This is called the stack effect.

Attic ventilation is the top of the chimney and crawlspace ventilation is the bottom.

As air is drawn up through your house, moisture, mold spores, odors and soil gases from the crawlspace find their way into the living space.

The Solution

Crawlspace encapsulation involves sealing the underside of the floor with a Closed Cell Polyurethane spray foam application and covering the ground using a tough 15-20 mil, reinforced polyethylene sheeting (not some thin 6 mil poly) taped carefully at the seams and adhered to the top or bottom of the concrete foundation wall.

Sealing up all ventilation entering the crawlspace is a specification 'if' it is decided that ventilation is not necessary for mechanicals. Sealed below this sheeting are soil gases, moisture, water vapor and odors that typically would be drawn up into the living space above.

The Solution

We are very proud of our projects because our specs are superior and our prices even better! We do not pay any enormous franchise or licensing fees to national companies and therefore, we are able to design a system that fits your home and your budget.

Building Science Experts

Nobody understands the science of building better than .

If you want to build a thermally efficient and airtight home, it's not enough just to insulate. You must choose the right insulation and air sealing system for the application, and be sure it's properly installed.

Did you know.. An improperly insulated and sealed home delivers 4500 lbs. of excess greenhouse gases into the air each year? It can also waste 20 percent or more of the energy used to heat and cool the home.

Our Building Science experts understand the principles of heat, air and moisture flow, and how the building envelope interacts with a building's mechanical systems as well as its occupants.

N.A.S.A. applied one-inch of spray-on foam insulation on the Space Shuttle's External Tank that serves to insulate the tank. The closed-cell foam used on the tank was developed to keep the Shuttle's liquid hydrogen fuel at minus 423 degrees Fahrenheit and the liquid oxygen tank at near minus 297 degrees Fahrenheit even as the tank sits under the hot Florida sun while preventing a buildup of ice on the outside of the tank.

Properly insulating and sealing your homes with Spray Foam is a greener alternative.

We can help you in specifying the right insulation system for our local climate. Call or Fill Out Our Contact Form to Get in Touch with our Building Science experts.

It is now well established and accepted by most architects and builders that controlling air infiltration is the best and most cost-effective means of reducing wasteful heat loss and providing a comfortable indoor environment.

Most architects tend to design structures that are tight and energy efficient by incorporating the latest in proven, energy saving construction details into their drawings.

Unfortunately, too many buildings still perform poorly. Why is this?

We have found that since there is no performance specification to dictate building construction, there is no guarantee when it comes to building performance. Regardless of the contractor's ability, tight buildings are not created from a list of materials and drawings in the absence of specifications that dictate the building's designed environmental performance.

takes a different approach

To improve building performance, our company focuses on the basic building science principle that air infiltration compromises the effectiveness of the building envelope. Our approach is incremental - areas of infiltration are diagnosed and fixed in order of magnitude. This provides the most thorough and cost-effective solution possible.

has satisfied clients. Our clients have been extremely pleased as they benefit from cost-savings and an immediate improvement in comfort.

We operate two-part urethane injection equipment to superinsulate new and old buildings. Included in this equipment are special nozzles and guns to seal cracks and small openings which effectively stops infiltration that cause poor thermal performance.

There are other urethane contractors who provide typical spray foam services; however, very few go beyond the installation of conventional spray-roofing and spray-wall insulation processes.

Our capabilities, while serving these common markets in some cases, are specially designed to meet the unconventional needs of specialty markets.

By employing standard and custom equipment which processes foam through both spray and injection techniques, we can utilize numerous chemical systems with varying densities, speeds, closed-cell content, fire rating, vapor permeability, and other desirable environmental characteristics.

While there may be other foam contractors who provide spray and injection services, to the best of our knowledge, we are the only company that currently uses "ratio monitoring" equipment in the field for this process. Ratio monitoring enables our technicians to maintain the exact chemical formulation (mix) for the duration of the installation process.

It is impossible to guarantee that the appropriate mix is being maintained without the use of this equipment.

WHY CHOOSE US

PREMIER INSULATION

We start with a complimentary, in-home consultation with one of our licensed insulation experts. You will be quoted fair prices - with no hidden fees - and provided with a reasonable installation timeline from start to finish. Our estimates are sent directly to your email inbox, where you can see line-item pricing as well as terms and conditions.

We Keep Our Promises

Trust is the cornerstone of our long-term success. We have served thousands of happy clients and look forward to serving you!

YOU'RE IN GOOD HANDS

WE DO IT RIGHT

We show up on time, maintain a tidy job site and perform high-quality work.

WE DO IT SAFELY

Keeping you and your family safe is the most important thing we do.

WE STAND BEHIND OUR WORK

has the best warranties in the business.

WE GUARANTEE YOUR SATISFACTION

Frequently Asked Questions

spray foam insulation is professionally installed at the same point in the construction cycle as other types of insulation. That is, it should be installed after the rough plumbing, electrical wiring, and heating and air conditioning ducts have been installed, but before the interior walls are completed in new home construction. In some cases spray foam also can be applied in older homes, to the inside of roofs and under floors after construction has been completed.

A two-part mixture is applied by trained applicators to the inside surface of exterior walls, to the underside of the roof, and beneath floors in basements and crawlspaces. The spray mixture expands rapidly to fill all cracks and voids, completely and permanently adhering to wood, masonry, metal studs and joists.

There are two basic types: closed-cell, rigid spray foam and "soft" or semi-flexible open-cell spray foams. See the article Learning the Difference between 1/2-lb and 2-lb Spray Polyurethane Foam for more information.

Both systems offer significant advantages over fiberglass batting: ability to air seal; ability to fill cracks and conform to odd shaped cavities; and ability to hold their shape over time and under adverse conditions.

But only closed-cell foam has the thermal insulation value (R-value) to bring your home up to Energy Star® standards with only one-half the thickness required for fiber insulations.

In addition, closed-cell foam products increases the strength of you wall system (it's approximately doubled) and increase the water resistance of your home's exterior.

Unlike cellulose and fiberglass materials, closed-cell foam is impervious to water absorption and wicking. Yet, like Gortex® fabric, the closed-cell structure allows the passage of water vapor (high energy particles) to allow your home envelope to "breathe".

Liquid water has much larger particles and is unable to pass into or through a closed-cell foam barrier.

-

You won't need house wrap with our system.

The air and moisture sealing effects of the spray polyurethane insulation are far superior to what house wraps can do. Don't waste your money on house wrap if you are insulating with spray polyurethane. -

You can encapsulate your entire exterior house shell with spray polyurethane.

This reduces energy loss from recessed lights and drop ceilings while minimizing any chance of frozen pipes in colder climates. In effect, this creates conditioned space everywhere including attics, basements, and crawlspaces. When ductwork is run through these areas, it is kept within conditioned space, substantially increasing the energy efficiency of your home. -

Spray polyurethane insulation will conform to any size or shape cavity.

Bay windows, oval windows, angled walls, sloped ceilings, or any other unusual framing designs can be well insulated and tightly sealed the same as the uniform spaced stud walls.

Several:

Our spray polyurethane insulation is sprayed on as a liquid which reacts and expands in place. This expansion action also seals all of the cracks and crevasses in your wall's exterior sheathing. The result is that air can no longer slip in: your house will be less drafty and more comfortable.

Air leakage can also introduce moisture into the wall cavity, resulting in wet insulation and mold and mildew. With the sealing effects of our spray polyurethane insulation, this will not be a concern.

Most house design professionals will advise you to seal the house structure as tight as possible and provide the necessary ventilation through the heating and air conditioning system.

Many systems employ an "air exchanger" which is designed to pre-condition (either warm or cool) the incoming outside air with the outgoing exhaust air.

In this manner, you can build an extremely energy efficient exterior shell using spray polyurethane foam while still providing controlled and energy efficient ventilation.

Yes. Building codes provide for the use of spray polyurethane insulation in the Foam Plastic section. This section of the code also describes the use of thermal barriers.

Normally spray polyurethane insulation is installed at the same point in the construction cycle as other types of insulation. That is, it should be installed after the rough plumbing, electrical wiring, and heating and air conditioning ducts have been installed.

If you decide to seal the entire exterior house shell with spray polyurethane, spray insulation may need to be applied in some areas before the ductwork is installed.

Yes. A popular retro-fit use for spray foam insulation calls for foam to be sprayed directly to the underside of roofing system.

This replaces the conventional blown in insulation used in the ceilings. Spray Foam can also be applied in the basement / crawlspace to eliminate air infiltration from the ground.

Our newest technology is Injection Foam; injection foam is used to fill existing walls by drilling small holes and injecting the foam from the outside of the structure.

- Glass fiber batts will not stop air leakage (it might filter out some dirt and dust).

- Blown-in cellulose will slow down air leakage.

- Spray polyurethane insulation will fully stop air leakage.

- Glass fiber batts have an R-value of about 3.5 (1-inch thickness).

- Blown-in cellulose has an R-value of about 3 to 4 (1-inch thickness).

- Spray applied polyurethane insulation has an R-value of 6.5 to 7 (1-inch thickness).

- Glass fiber batts can sag over time.

- Blown-in cellulose can settle over time.

- Spray polyurethane insulation completely adheres to wood and sheathing and is rigid; the result is a permanent barrier to heat loss and air entry.

- Spray polyurethane insulation will add strength and rigidity to your house. Glass fiber batts and blown-in cellulose will not.

Air Leakage:

R-value:

Lasting Ability:

Yes! The installed cost of spray polyurethane is somewhat higher than traditional fiber batts or blown-in cellulose. However, the higher initial cost is partially offset because you need not ventilate the roof, the HVAC system is downsized and you will save in your heating fuel and electric bills.

Studies suggest that homes insulated with spray polyurethane use 35 to 60 % less energy than homes insulated with conventional insulation. Your savings may be greater or less depending on your life style, appliances, house site, number and size of windows, etc.

When first installed, spray polyurethane foam's R-value is about 10 for a one-inch thickness.

Over time, the R-value drops to between 6.5 and 7.0 (one inch) and stabilizes at that value. The time it takes to reach an R-value of 6.5 to 7.0 depends on a variety of factors, including total foam thickness.

We report a six-month aged R-value. Many industry studies indicate that a one-inch thick sample of foam will stabilize after six months and maintain that approximate R-value for decades.

Spray polyurethane can be applied directly to electrical wiring. Recessed lights or other fixtures may require a certain amount of air circulation around them for cooling purposes.

In these cases, a box can be build around the fixture with gypsum wall board; then spray foam can be sprayed directly to the outside of the box.

Not that we're aware of. We've looked at 20-year old spray foam projects and we have not observed any signs of deterioration. We expect our spray polyurethane insulation system to insulate and seal your home for the life of the house.

Spray polyurethane foam was commercially developed in the United States in the mid-1960's. Homes have been insulated with spray foam since that time.

Most moisture problems in houses are due to moisture entry from air leakage. Because spray polyurethane insulation provides such an excellent air barrier, this source of moisture is virtually eliminated.

Other potential sources of moisture can be excluded with proper construction techniques and materials. Unusual building use (such as freezers or swimming pool buildings) may require a vapor retarder.

No.

Required equipment elements include a plural component proportioner pump with heaters, dual high pressure heated hoses, high pressure mixing and spray gun, and feed pumps and hoses. In addition, an air compressor and electrical generator may be needed.

Not practically. Spray polyurethane application requires complex equipment and a skilled installer.

Yes! Our closed cell foam is rigid and structural. Your walls will be more resistant to winds and you'll notice less creaking and shaking when doors are slammed or when the kids are romping about.

Quite quickly. A typical 2000 sf house can be fully prepped and insulated with spray polyurethane in less than several days. Large houses or houses with complex design features could take longer.